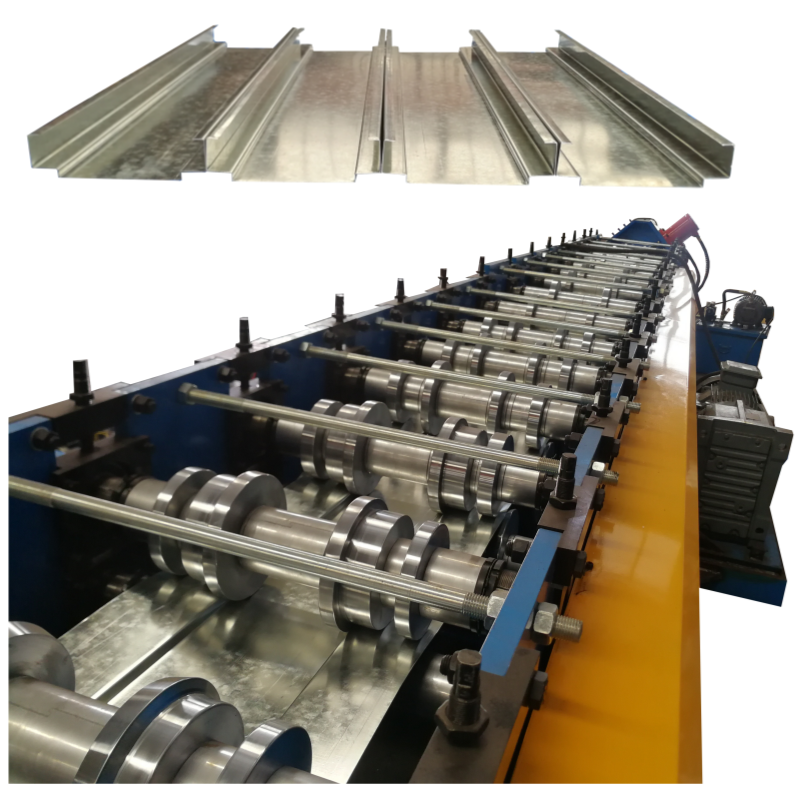

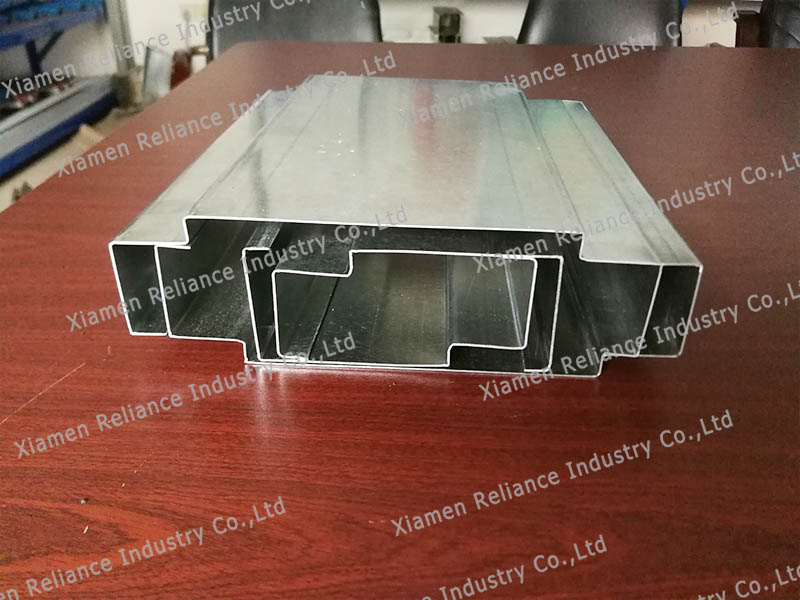

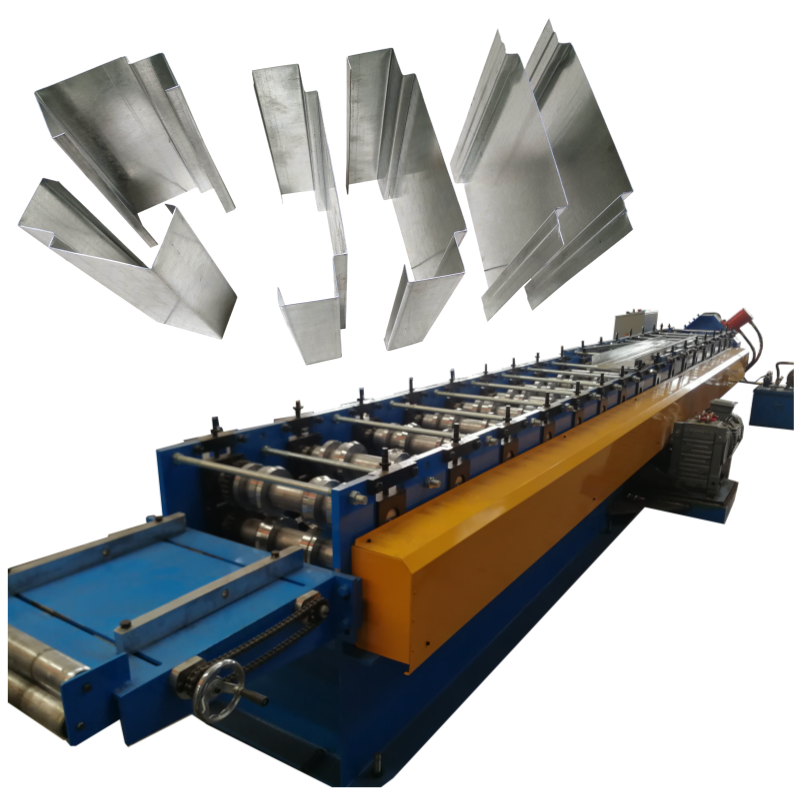

RELIANCE High-end Double Sides Door Frame Forming Machine

Reliance offer on-site installation, training and maintenance if have demand.

Packaging & Delivery

Packaging Details:

Nude place in container, machine body tightened with steel wire rope and base frame position fixed by heavy steel angle plate. Roller groups cover with waterproof cloth. Computer control system packed with plywood box. Tooling box and regular wearing parts packed with plywood box as well.

Loading Port: Xiamen Port, China

Machine Leading Time: 70~90 Days

Technical Details

The Line’s Specifications | |

Weight | About 6150gs |

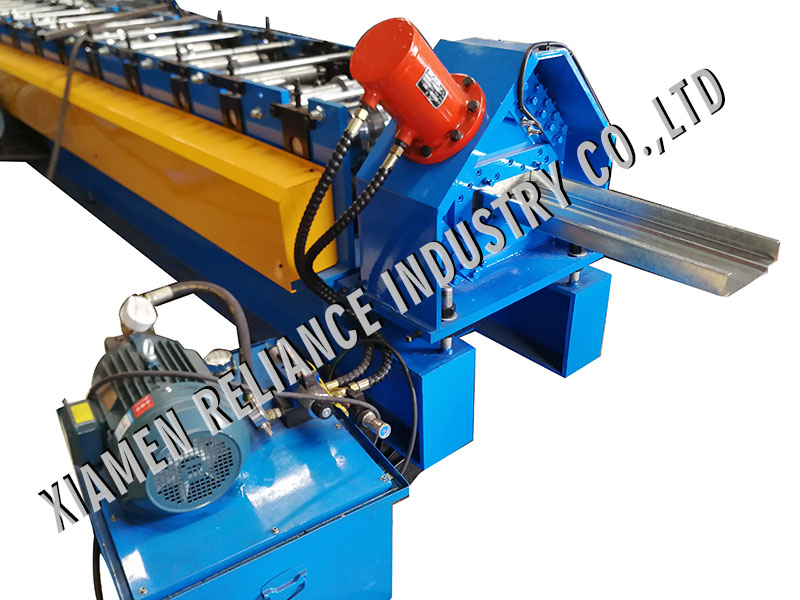

Whole line’s dimension | About 11.5m x 1.6m x 1.2m (length x width x height) |

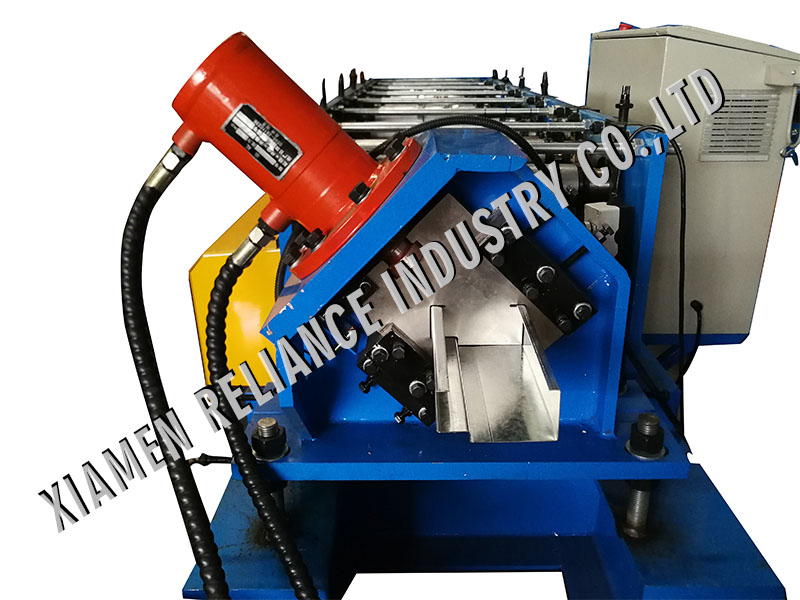

Color | Main color: blue |

Warning color: yellow | |

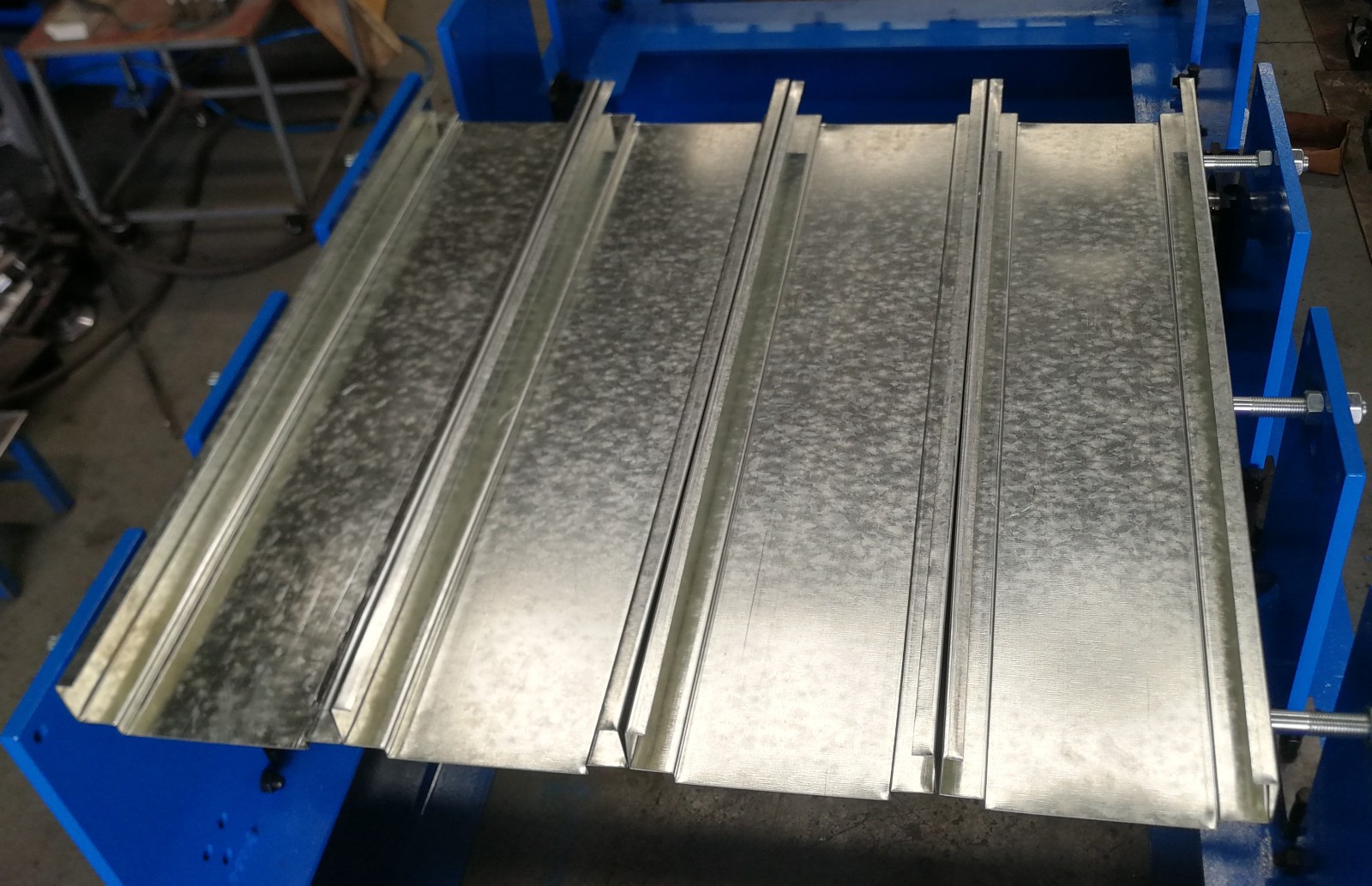

Suitable Raw Material | |

Material | Galvanized or Galvalume Coils |

Thickness | 0.8-1.5mm |

Coil width | According to products size, many sizes available |

Yield Strength | 550Mpa |

Main Technical Parameters | |

Quantity of forming rollers stations | About 17 |

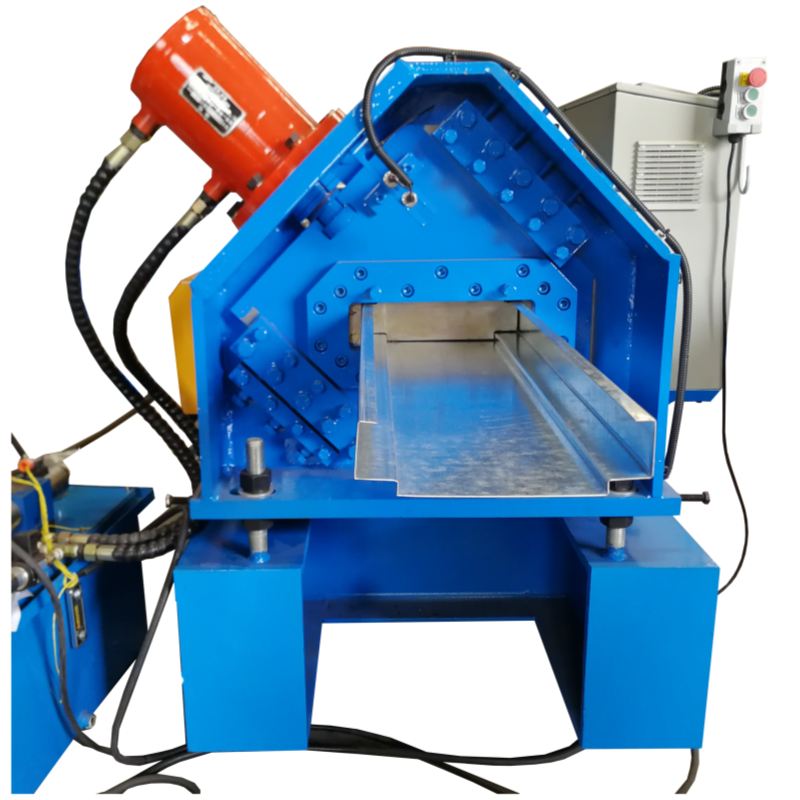

Diameter of forming rollers shafts | 75mm |

Roll Forming Speed | 15m/min |

Production Speed | 8m/min as per order length |

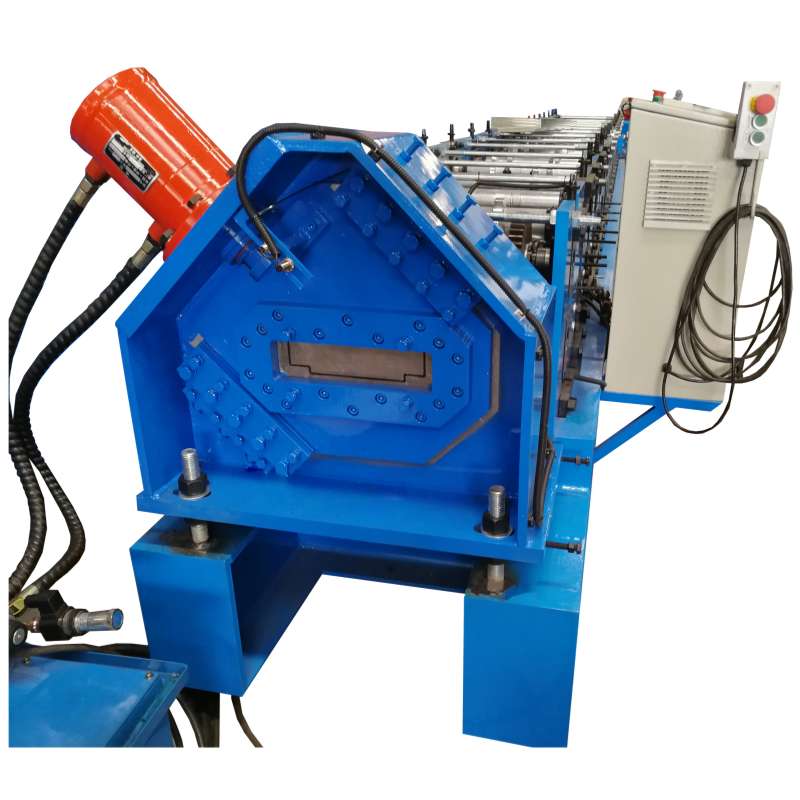

Forming rollers material | Gcr15 mould steel, with quenched treatment |

Cutter material | Cr12 mould steel, with quenched treatment |

Controlling system | Combined with: PLC (Siemens), Touch Screen (Siemens), Inverter (Schneider), Encoder (Omron), etc |

Electric Power requirement | Main motor power: 25kw |

Hydraulic unit motor power:7.5kw | |

Electric voltage | According to customer’s requirement |

CZ & Sigma Purlin Machine

CZ & Sigma Purlin Machine